Infrastructure

At Tata Precision Industries, our infrastructure is the backbone of our success. We leverage cutting-edge machinery, a skilled workforce, and advanced quality control systems to deliver precision-engineered products that meet the highest global standards.

At Tata Precision Industries, we believe that the foundation of superior manufacturing lies in our state-of-the-art infrastructure. Our world-class facilities are equipped with cutting-edge technology and machinery that allow us to meet the high precision demands of industries such as Aerospace, Automotive, Telecommunications, Defence, and Life Sciences. Every component we produce reflects our commitment to excellence, innovation, and precision.

Our Manufacturing Facilities

Our manufacturing units are equipped with a wide array of advanced machinery that ensures high-quality, precision-engineered components. Our capabilities include:

CNC Machining Centers

Our facilities house advanced CNC Vertical and Turning Machining Centers from leading global manufacturers such as Fanuc, Makino, and Excel. These machines enable us to deliver high-precision parts with tight tolerances, supporting complex manufacturing needs across a range of industries.

Injection Moulding Machines

We utilize advanced injection moulding systems equipped with microprocessor controls to manufacture plastic components with unmatched accuracy and repeatability. This allows us to meet the stringent requirements of industries like telecommunications and healthcare.

Tool Room

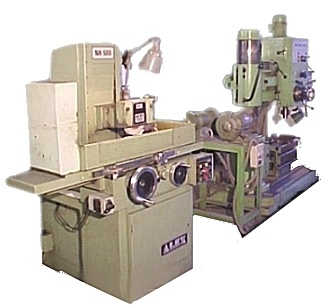

Our in-house tool room is equipped with CNC Milling Machines, Surface Grinders, Radial Drill Machines, and Lathes, all dedicated to the maintenance, repair, and manufacturing of custom tools, jigs, and fixtures. This ensures that we maintain full control over every aspect of the production process, guaranteeing the highest quality.

Quality Control Infrastructure

At Tata Precision, quality is not just a promise; it’s a process. We have invested heavily in modern quality control systems to ensure that every product meets the most rigorous international standards.

CNC Coordinate Measuring Machines (CMM)

Our quality control department is equipped with CNC CMM machines from Mitutoyo, Japan, ensuring that all components are measured and inspected to the highest standards of precision and accuracy.

Profile Projectors & Roughness Testers

We use advanced measurement tools like profile projectors and roughness testers to inspect every detail of the components we manufacture. This ensures flawless surface finishes and dimensional accuracy for even the most complex

parts.

Comprehensive Quality Management

Our ISO 9001:2015 certification reflects our commitment to quality and our adherence to international manufacturing standards. We apply advanced Statistical Quality Control (SQC) techniques, including Cpk and Cp analysis, to ensure consistency and performance in every product we deliver.

Sustainability & Innovation

Tata Precision Industries is committed to responsible and sustainable manufacturing. Our facilities are designed to optimize energy use, reduce waste, and minimize our environmental footprint. We are continuously innovating to improve the efficiency of our operations while maintaining our focus on high-precision output.

Through ongoing investment in new technologies and process improvements, we are able to maintain our competitive edge and deliver products that not only meet today’s demands but also anticipate future challenges.

Our Machinery at a Glance

At Tata Precision, quality is not just a promise; it’s a process. We have invested heavily in modern quality control systems to ensure that every product meets the most rigorous international standards.

HASS VF-3SS Super Speed Vertical Machining Center

Equipped with X-1016, Y-508, Z-635mm axes stroke, this machine offers unparalleled precision and speed for complex components.

Fanuc CNC Vertical Machining Centers

Boasting a table size of 650mm x 400mm, these machines deliver high-tolerance parts that are crucial for the automotive and aerospace industries.

Makino S-33 CNC Vertical Machining Center

This high-precision machining center features a stroke of X-650, Y-500, Z-450mm, ensuring accuracy and reliability for even the most intricate parts.

Mitsubishi CNC Wire Cut System & EDM System

These machines provide ultra-precision cutting and shaping, crucial for producing complex parts with exacting tolerances.